seed handling technologies.

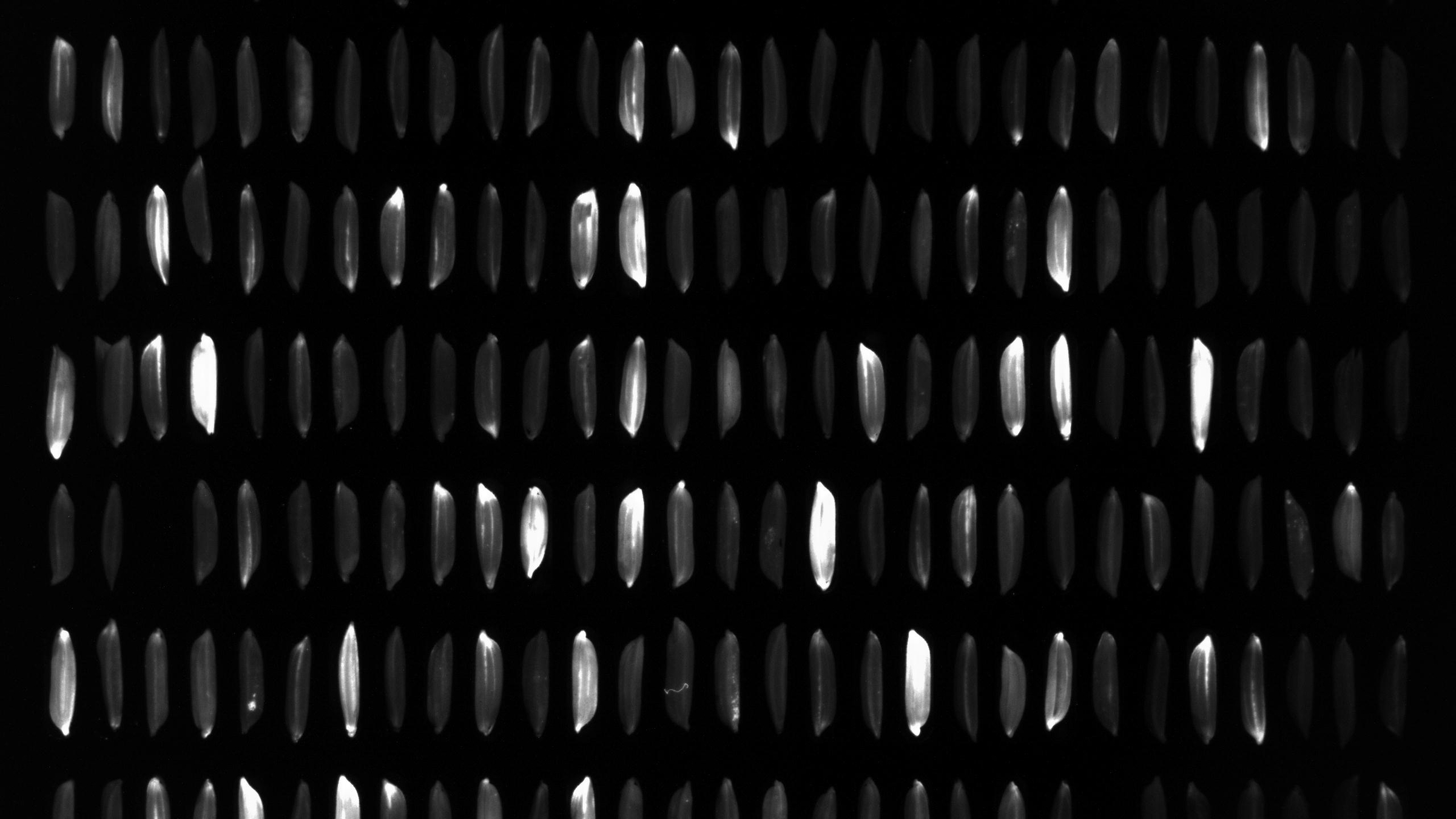

SeQso utilizes cutting-edge techniques to optimize the movement, separation, and control of seeds throughout the sorting and sowing processes:

- Conveyor systems & seed carriers – Streamlined transport for high-throughput workflows

- High-precision accept/reject separation – Enhanced quality assurance and batch-level control

- Accurate seed singulation – Reliable separation and positioning for downstream processing

multi-modal imaging for deep seed characterization.

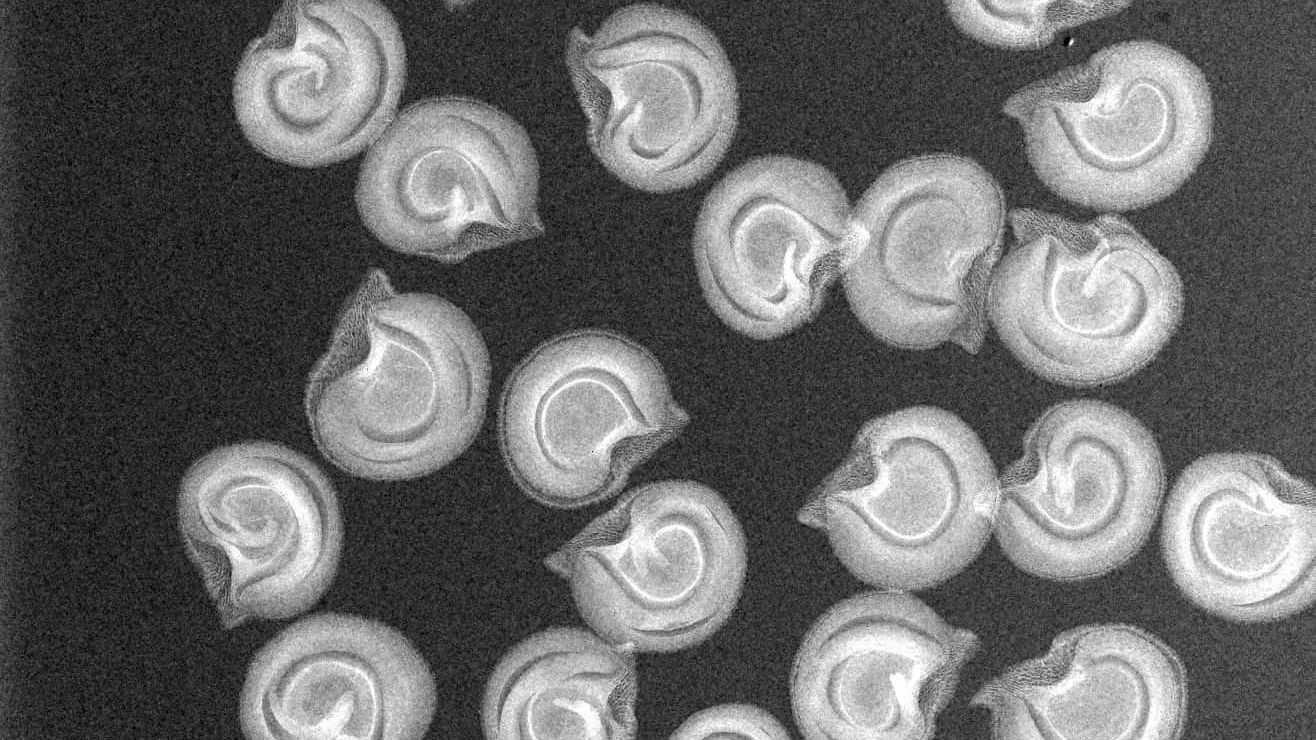

Advanced imaging modules deliver high-resolution insights into seed traits and quality:

- RGB imaging – Fast, color-based classification

- X-Ray imaging – Internal structure and defect detection

- Fluorescence imaging – Marker-based analysis including chlorophyll, anthocyanin, and GFP

- Hyperspectral imaging (VIS, NIR, SWIR) – Spectral profiling for biochemical composition

- 3D profiling – Shape and structure measurement for enhanced sorting precision

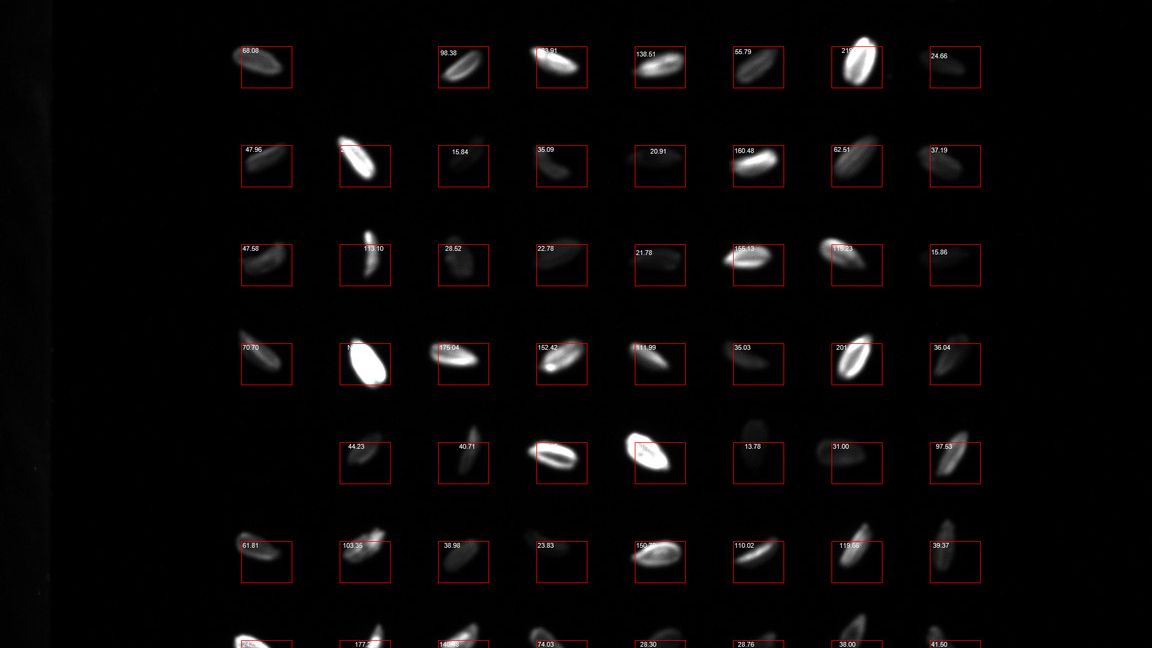

data processing & classification.

SeQso combine traditional and AI-driven methods to enhance seed classification accuracy and process automation:

- Advanced Classification Models – Classical, modern, and custom-developed classification techniques

- AI Modeling & Deep Learning – Deploying of basic machine learning models for optimized sorting

- ERP & Tracking System Integration – Seamless connectivity with business operations

- Database Support – Scalable data storage and retrieval solutions for analysis and reporting

empowering data-driven decisions smarter insights, faster action, greater impact.

"SeQso delivers actionable intelligence by seamlessly integrating advanced technologies across seed handling, imaging, and data processing. This empowers seed breeders and producers to make confident, data-driven decisions at every stage of their operation. With a unique combination of technological innovation and deep biological expertise, SeQso drives measurable improvements in precision, productivity, and performance—setting a new global industry standard for operational excellence in seed processing."